Previously, I talked about removing some hardware from the crossbar of a set of shafts. This singletree yoke was held to the wood with two small (roughly #8 x 3/4") wood screws which were solidly frozen and would not turn with an ordinary screwdriver.

Heat is commonly applied to frozen screws to loosen them. For this job, I used an industrial propane soldering iron. I believe that an ordinary soldering iron can also be applied to the head of the screw to heat it.

We had this tool on hand, so I used it, assuming it would become hotter and work more quickly. For these small screws it took only about a minute of applying the tip of the soldering iron to the screw head to loosen the screws and extract them easily, as shown above.

At this time, I wish to remove the seat from the carriage body in order to begin preliminary repairs that will benefit from the warm dry weather for curing. I am now presented with a much more difficult problem; extracting seven very large, very long,solidly frozen screws which hold the seat to the body. I have been worried that applying heat to the heads of such long, large screws would not be successful. However, as it turns out, the application of a cherry-red-hot soldering iron tip to THREE of the screws was sufficient to loosen and extract them. The remaining four would not budge.

I held the soldering iron tip to the screw head for up to four minutes, as the surrounding paint began to blister. But a cold water quench - another suggestion for loosening screws - did not even cause the screw heads to sizzle. I tried inserting the screwdriver into the slot and striking the handle with a hammer, another suggestion for dislodging frozen screws. Nothing happened.

My husband suggested the use of a very fine tipped acetylene torch. This tiny torch is wickedly hot! A large washer was placed on the wood surrounding the screw head to hopefully help protect the wood from the flame. Holding the pinpoint flame over the screw head for a very short time (on account of the wood).

The torch was sufficient to loosen ONE screw without scorching the wood. Three remained solidly frozen.

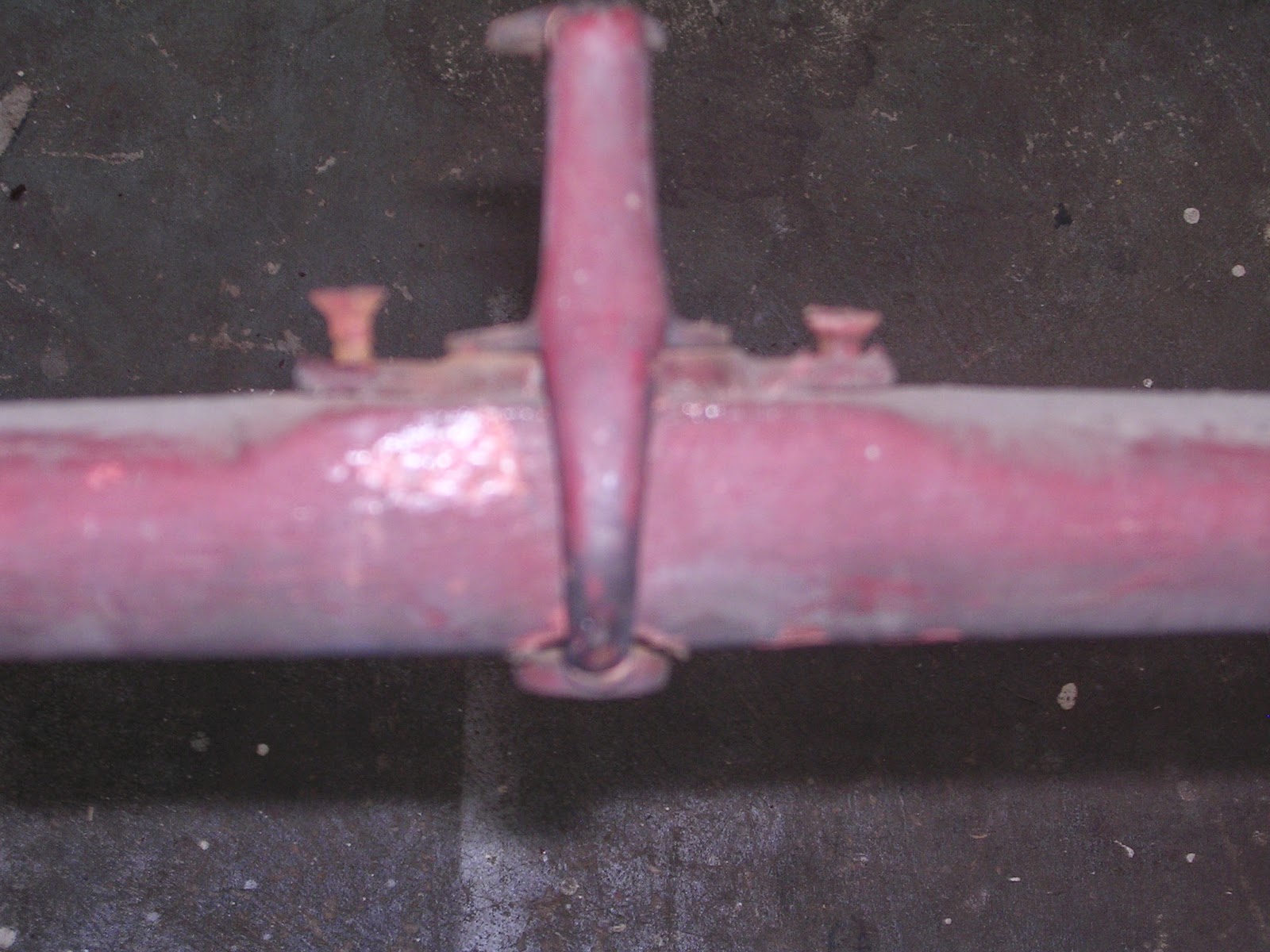

Our last assault on the remaining screws involved this tool. It is a "hand impact screwdriver" that is capable of converting a hammer blow to 200 foot pounds of torque. The bit is driven down into the slot while creating a twisting action.

Eventually, two more screws gave way to this tool.

The last one required the application of the torch AND the impact screwdriver to break free, but it, too, was extracted without damage to the screw or the wood.

The screws were even larger and longer than I expected; 1/4" in diameter and 2" long. I have no idea why the maker was so worried about the seat flying off!

But eventually it did! And now the seat is ready to have the upholstery removed and begin the repair processes that are best done as early in the restoration as possible.

PLEASE NOTE: The use of a hand impact screwdriver to loosen screws in more fragile panels might carry the risk of splitting the panel. These screws held rock hard oak framing members together. I believed the use of the screwdriver would cause less damage than the prospect of gouging the wood out and trying to extract the screws with a pair of vise-grips!

So, if you're faced with the prospect of removing rusted, frozen wood screws, try:

- Applying heat to the screw head.

- Apply a cold water quench after heating.

- Insert a screwdriver into the slot and rapping the handle with a hammer.

- Try a hand impact screwdriver. They are not very expensive.

- Drill a series of holes in the wood surrounding the screw head and chip the wood out around the screw. Repair the wood later by gluing a piece of dowel into the damaged wood.

Any other suggestions are welcomed. This is a common and serious obstacle encountered in carriage restoration.

No comments:

Post a Comment